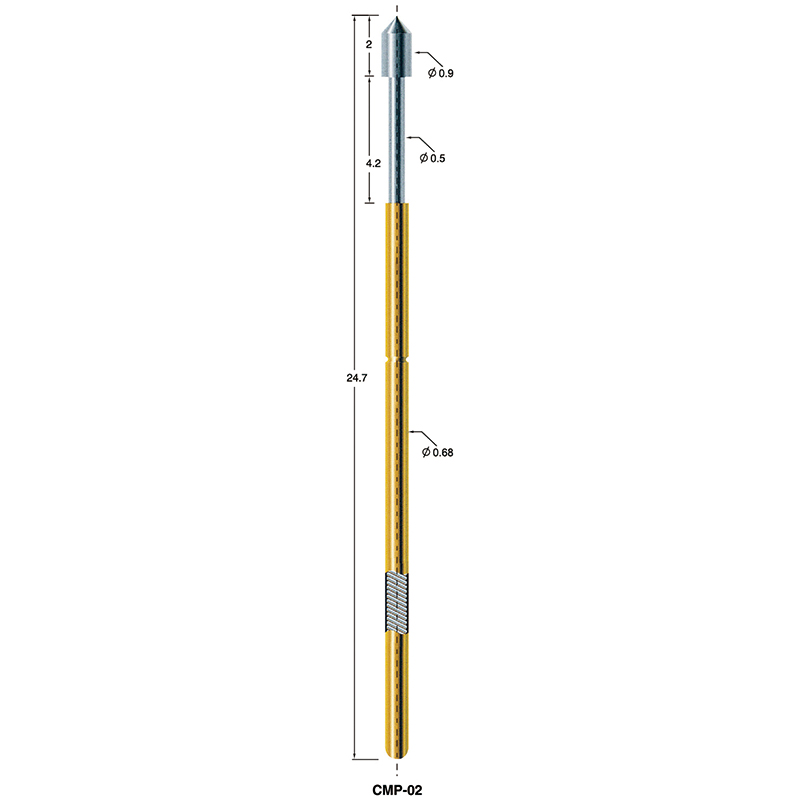

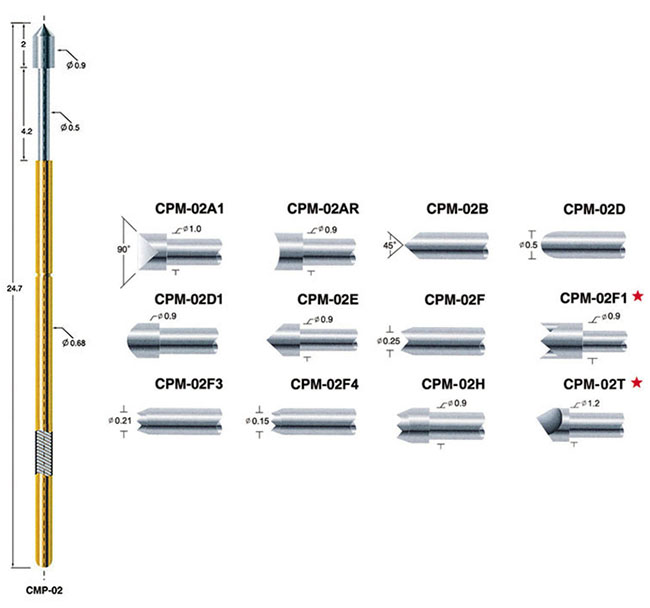

CPM-02 / R-02

Welcome to contact us.

Unit : mm

| Mountiong hole size |

| Φ 0.95 /.0374” |

| Probe specifications CPM-02/R-02 | ||

| Recommended min. center | 1.27 (.0335") | |

| Full travel | 4.2(0.165" ) | |

| Current rating | 3A | |

| Contact resistance | 30mΩ | |

| Spring force | 120g | |

| ★ code for customized products | ||

| Materials and finishes | ||

| Plunger | SK4, NI plated | |

| Barrel | Phosphor bronze, Gold plated | |

| Spring | Stainless Stee | |

The Bare Board Test Probe is an essential component used in the testing of printed circuit boards (PCBs) to ensure their functionality and reliability.

During installation, the probe requires mounting holes with specific dimensions to securely fit onto the PCB. The recommended mounting hole size for the Bare Board Test Probe is Φ 0.95 /.0374". This size allows for precise installation, ensuring a snug and stable fit.

The Bare Board Test Probe, designated as CPM-02/R-02, has specific specifications that contribute to its performance. The recommended minimum center distance between probes is 1.27 (.0335"), which allows for proper spacing and prevents interference during testing. The probe offers a full travel distance of 4.2 (0.165"), providing sufficient contact with the PCB for accurate testing. It has a current rating of 3A, ensuring it can handle the electrical demands of the PCB under test. The contact resistance of the probe is 30mΩ, indicating a low resistance value for reliable signal transmission. The probe exerts a spring force of 120g, providing the necessary pressure for stable and consistent contact with the PCB.

The Bare Board Test Probe is made of high-quality materials to ensure durability and performance. The plunger is made of SK4 and is nickel plated, offering excellent wear resistance and electrical conductivity. The barrel is constructed of phosphor bronze and is gold plated, providing corrosion resistance and reliable electrical contact. The spring is made of stainless steel, known for its strength and resilience.