CPM-60 / R-60

Welcome to contact us.

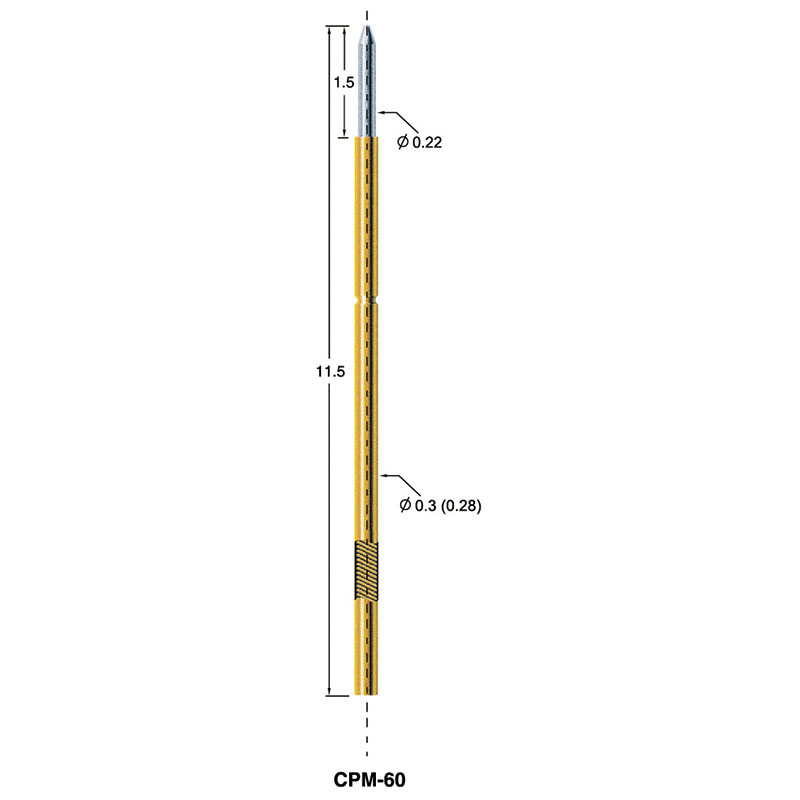

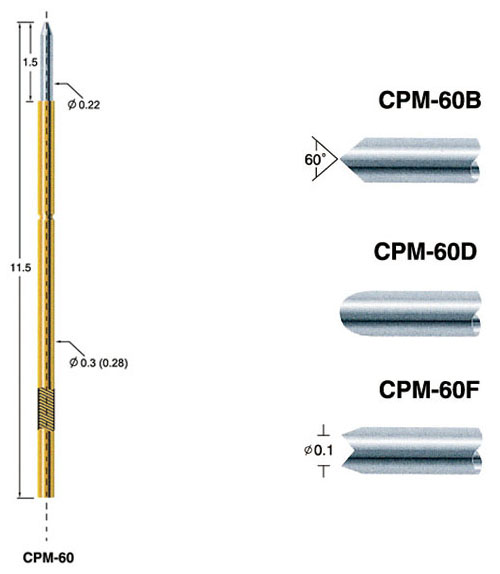

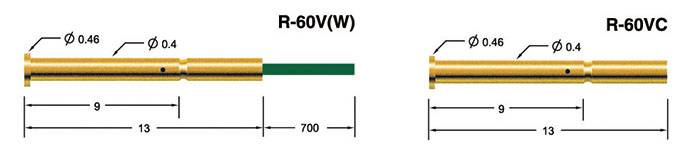

Unit : mm

| Mountiong hole size |

| Φ 0.42 /.0165” |

| Probe specifications CPM-60/R-60 | ||

| Recommended min. center | 0.6 (.0236") | |

| Full travel | 1.5(0.059" ) | |

| Current rating | 0.5A | |

| Contact resistance | 200mΩ | |

| Spring force | 30g | |

| ★ code for customized products | ||

| Materials and finishes | ||

| Plunger | SK4, Ni plated | |

| Barrel | Phosphor bronze, Gold plated | |

| Spring | Stainless Steel | |

Receptacle specifications

• Materials and finishes Phosphor bronze,Gold plated

The Bare Board Test Probe is an essential tool used in the testing and evaluation of bare printed circuit boards (PCBs) before the assembly of electronic components. It ensures the functionality and reliability of the PCBs by conducting various electrical tests.

During the mounting process, the probe requires a specific hole size for proper installation. In this case, the recommended mounting hole size is Φ 0.42 /.0165". This precise hole size allows for a secure and accurate fit, ensuring proper electrical contact between the probe and the PCB.

The Bare Board Test Probe, specified as CPM-60/R-60, follows specific specifications to ensure accurate and consistent testing results. The recommended minimum center distance between probes is 0.6 (.0236"), providing optimal spacing between probes for effective testing and minimizing interference between neighboring probes.

The probe has a full travel distance of 1.5 (0.059"), indicating the maximum range of motion during testing. This range allows comprehensive testing coverage and analysis of the PCB's performance, ensuring that all critical areas are thoroughly evaluated.