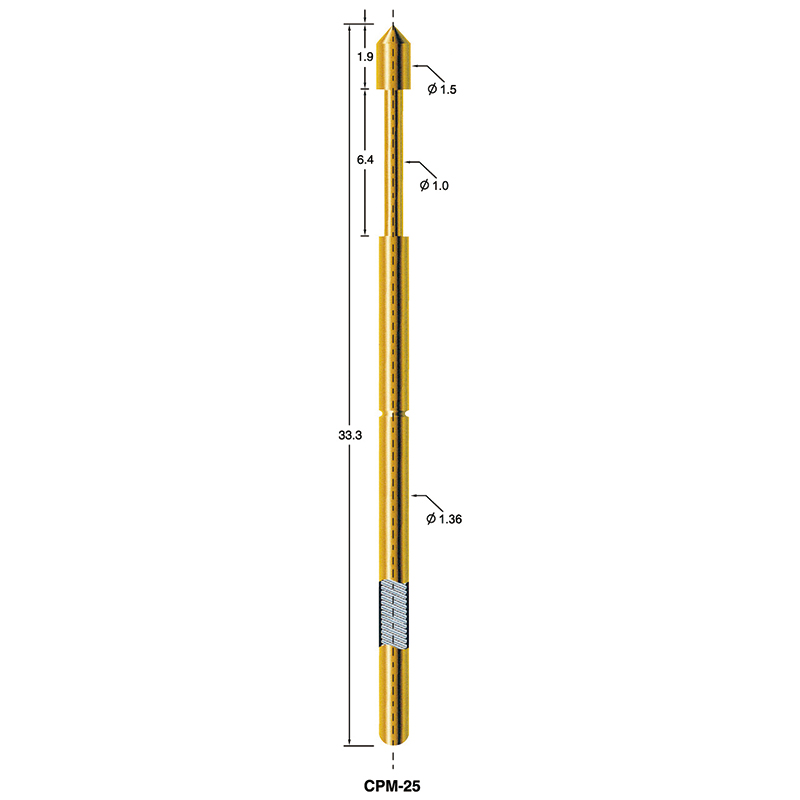

CPM-25

Welcome to contact us.

Unit : mm

| Mountiong hole size |

| Φ 1.75 /.0689” |

| Mountiong hole size |

| Φ 1.7 /.0669” |

| Probe specifications CPM-25 | ||

| Recommended min. center | 2.54(.1") | |

| Full travel | 6.4(0.252" ) | |

| Current rating | 5A | |

| Contact resistance | 50mΩ | |

| Materials and finishes | ||

| Plunger | Be Cu,Au plated | |

| Barrel | Brass, Gold plated | |

| Spring | Stainless | |

For secure mounting of the Loaded Board Test Probe onto the PCB, specific mounting hole sizes are required. The recommended mounting hole sizes for this probe are Φ 1.75 /.0689" and Φ 1.7 /.0669". These precise hole sizes ensure a proper fit of the probe, enabling a secure and accurate installation onto the PCB. This secure fit guarantees reliable electrical contact between the probe and the loaded PCB, facilitating precise and dependable testing.

The Loaded Board Test Probe conforms to the CPM-25 specification, which outlines the probe's characteristics and capabilities. The recommended minimum center distance for this probe is 2.54 (.1"), ensuring adequate spacing between probes to avoid interference and crosstalk during testing. This optimal spacing allows for accurate measurements and reliable evaluation of the PCB's electrical performance.

The materials and finishes used in the construction of the Loaded Board Test Probe are carefully chosen to ensure optimal performance. The plunger is made of Be Cu (beryllium copper) and is gold plated. This combination of materials provides excellent electrical conductivity and corrosion resistance, ensuring reliable and accurate test results. The barrel is made of brass and is gold plated, which further enhances electrical conductivity and protects against oxidation. The spring is made of stainless steel, providing resilience and durability for repeated use.